Top of the SCOP winners

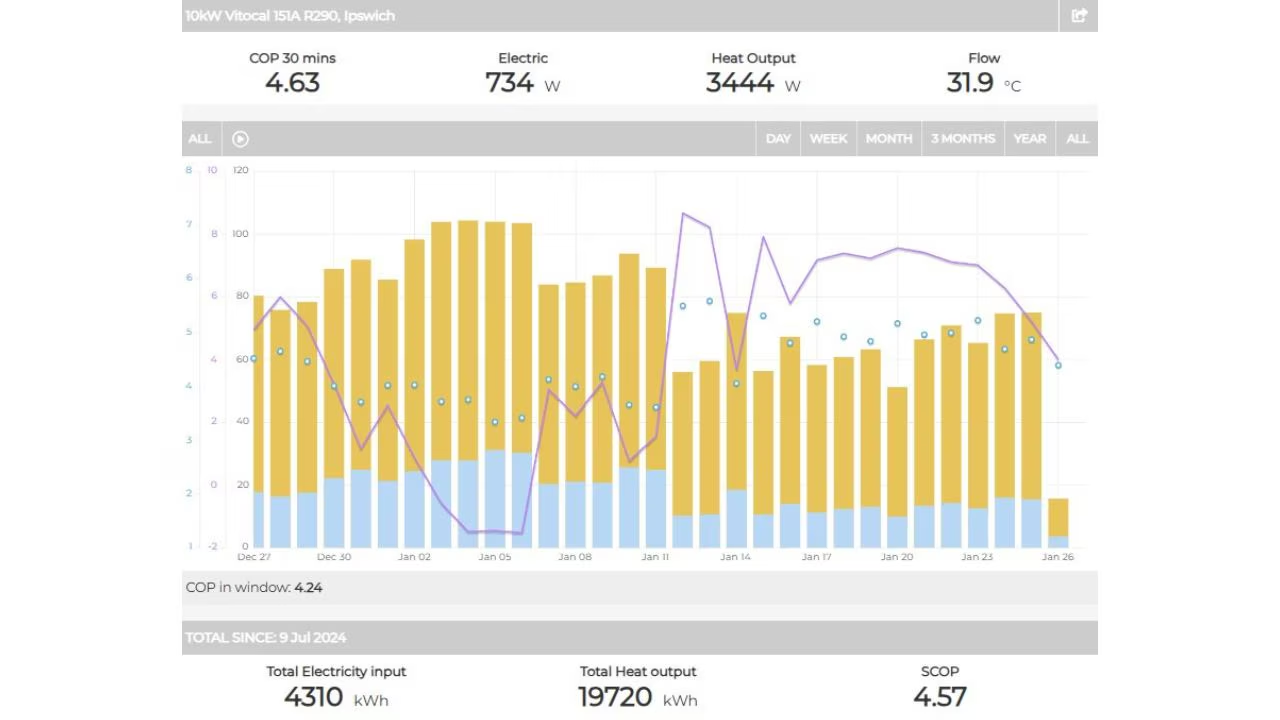

The two joint-winning installations of the Top of the SCOPs competition, with an average SCOP of 4.5 at the 12 month closing date, were a detached 2016 property in Rednal, Birmingham, with fully insulated walls, floors and loft by NMB Heat Pumps; and a 1930s-built detached chalet bungalow in Ipswich, with cavity wall and some loft insulation, installed by Sun-Lite Group Ltd.

The remaining finalists were Custom Renewables and its installation in Aylesbury, Arran Woodford of York, Ecoerne Consulting with a property in Derrygonnelly, Optimus Heating in Horsham and Peter Hamilton of Berwick-upon-Tweed. Three finalists’ data were not collected in full at the competition’s closing date due to connection issues. The currently connected finalists’ live installations can be viewed here in order of their performance over the past 12 months.

“Heat Pump Monitor is regarded by the HVAC industry as the best open source picture of real-world heat pump performance from the top installations in the country, involving 205 different installers and 20 different manufacturers’ products. While the average SCOP among all 252 ASHP installations with independent billing grade metering on the platform is 3.87, installations using the Viessmann Vitocal 150-A heat pump range return one of the highest overall average SCOPs, of 3.96 (as at January 26th 2026). We are delighted therefore to see our seven finalists raise the game within this already highly competitive data set to achieve an average SCOP of 4.1. between August 2024 and August 2025. This uplift is down to their quality heating system design and installation, and we congratulate them,” says Cameron Beech, Head of Product Management at Viessmann Climate Solutions UK.

“Many of our finalists have been designing low temperature heating systems and fitting Viessmann products for a decade or more – their work signals the efficiency wins that are possible for our industry as it goes from strength to strength,” concludes Cameron Beech.

Glyn Hudson, Co-founder of Open Energy Monitor, said, “The biggest winner of the Top of the SCOPs competition is the heat pump concept itself – the data on our platform shows that even in period homes of 100 years old or more and those built in solid stone that heat pumps can be cheaper to run than gas or oil boilers. While Top of the SCOPs is rightly about applauding some of the very best installers in the country, the data suggests that the success of the Viessmann Vitocal range is its ability to work well as a ‘drop-in’ solution to a wide range of installations. Advanced integrated features such as the defrost buffer vessel take care of installation aspects that otherwise fall to the expertise of the installer.”

Sharing and optimising heat pump performance across the year

One of the most common consumer concerns about heat pumps relates to achieving warm room temperatures on the coldest days. During the 12 month period studied, the average temperature of the coldest day was -2 °C. However, the Vitocal heat pumps generated an average flow temperature of 35 °C and an average indoor temperature of a comfortable 19.5 °C. Even in minus temperatures, the average COP, the efficiency measurement for just the coldest day rather than across a year, was 3.0.

Monitoring heat pump performance via Heat Pump Monitor allows installers to analyse and improve their installations over the year and across different outside temperatures.

Other high performers

Many heat pump installations by Viessmann partners connected to the Heat Pump Monitor return a SCOP of 4.5 and above. The ASHP installation on Open Energy Monitor that produces both heating and hot water the most efficiently in the coldest average UK temperature, with a platform SCOP topping 5.4 at certain times of the year, is a Vitocal 150-A in an Edwardian home in Sheffield listed by heating engineer, Damon Blakemore of Blakemore Plumbing, Heating & Renewables.

[1] Electrification of Heat Demonstration Project, Department for Energy Security and Net Zero (DESNZ)

[2] The launch of Viessmann Climate Solutions’ ‘Top of the SCOPs’ competition can be viewed accessed here.

Pictured: performance data for 12 months up to January 26th for Top of the SCOPs competition joint winner: Ipswich home by Sun-Lite Group Ltd.

Pictured: performance data for 12 months up to January 26th for Top of the SCOPs competition joint winner: Ipswich home by Sun-Lite Group Ltd.